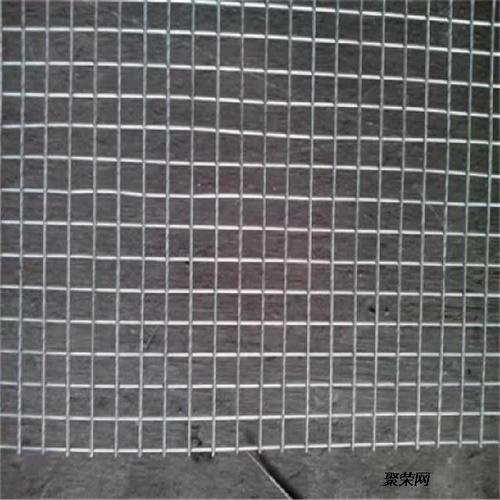

A net of wire strands, entwined together and held firmly in place, wire mesh can be used in a multitude of ways. It’s a popular option for industrial, commercial and residential applications like fencing, screening, reinforcement, and filtering. But it also serves in construction work like reinforcing concrete and assisting with the erection of walls. Truly, with its many uses and practical applications, wire mesh is a much-desired product.

The cost of wire mesh fluctuates depending on the material it is made from, the wire’s gauge, the measurements and number purchased. Steel wire mesh is the most popular and accessible choice, from light-duty options costing around $5 per ft., to the heavy-duty variations clocking in at up to $15 per ft.. This product is most generally sold in rolls.

If weight is a concern, aluminum wire mesh can be an attractive option compared to heavier steel variants. Cost-wise, this alternative usually runs more expensively compared to steel mesh, being priced at roughly $20/sq. foot for light varieties and up to $50/sq. foot for robust units.

Withstanding intense heat and dampness, stainless steel wire mesh is the most reliable material for applications exposed to moisture and extreme temperatures. Although on the costlier side, you can purchase light-weight mesh at approximately $25 a square foot and sturdier mesh up to around $100 per square foot.

Galvanized wire mesh is an economical option for a variety of outdoor uses, providing both excellent strength and corrosion resistance. This type of steel mesh is coated with a zinc coating to protect against rust and other damage from the elements, making it the optimum choice for fencing and screening applications. Prices for galvanized mesh range from approximately $7 per square foot for lightweight meshes to as much as $20 per square foot for sturdier varieties.

Plastic netting is a lightweight option with a wallet-friendly price. Most often used for tasks like filtering, sifting, and screening, its value can range from around two dollar bills per square foot for the light type of mesh to more than double that price for the heavy-duty kind.

When looking into purchasing wire mesh, it is important to get an accurate understanding of the type of mesh that would be most effective for the task. Taking the time to research various materials can help you determine the pros and cons of the different types. Remember to keep price in mind as well, as there can be a drastic difference in cost for each one.

Ultimately, wire mesh is a multifunctional material with a range of uses both at home and in professional settings. Its price usually depends on the type of metal it consists of, the grade of wire being used, the mesh size, and the volume you buy. Steel, aluminum, stainless steel and galvanized forms are highly popular on the market while plastic mesh is cheaper and has a lighter weight. When shopping around, make sure to take into account your goals as well as your budget when deciding which type of wire mesh best suits you.

Constructed from strands of metal, wire mesh is an interweaving of durable materials that offers a multitude of practical and decorative uses. From industrial operations to artistic designs, its strength and versatility make it an ideal solution to a variety of applications. Many use it for fencing, sieving, and screening while its attractive composition makes it ideal for adorning sculptures and artwork.

Great variance in the price of wire mesh can be attributed to several parameters, such as the size, type, and gauge of the material. The quality of the item is likewise a determinant – goods of superior quality often command a higher cost than poorer-grade materials. Bulk purchases meanwhile prove indeed to be the savvy shopper’s ally, as larger quantities are usually more economical than scantier amounts.

When making a wire mesh purchase, the assignment at hand should be taken into account. Commonly, welded wire mesh is the go-to due to its husky build and broad usage range. For decorative purposes, such as sculptures and art installations, woven wire mesh is the method of choice – it may not provide the same amount of sturdiness as welded, but can serve an ornamentation purpose. Going beyond these two options is expanded wire mesh, which although it’s not used regularly, it’s especially ideal for industrial activities like screening and sieving.

The cost of wire mesh may vary based on its size and the thickness of the wires used – the width and height of the mesh is known as the ‘size’ and the gauge offers insight into wire’s thickness. Generally, larger sizes and thicker gauges equate to higher costs. Steel is usually used to construct the mesh, but more people are opting for aluminum and stainless steel varieties.

When hunting for wire mesh, it’s wise to source from a trustworthy supplier. Exploring options from a few suppliers in the hopes of finding discounts on bulk orders can pay dividends. Furthermore, the descriptions of the wire mesh should be examined with great care to ensure accuracy regarding its quality and specifications – otherwise, costly surprises may await.

All in all, the cost of wire mesh is determined by many elements, such as quality of materials, dimensions, gauge, and quantity acquired. When buying wire mesh, it is essential to think about the kind needed for the assignment, alongside its size and gauge. Also significant is to secure a respected supplier and look at the item details attentively.

Related Product

Razor Wire

Product information: Concertina Razor Wire is widely used for construction of high security fencing projects in military and national defence. We export directly and supply Razor W […]

Welded Wire Mesh

Welded wire mesh is one popular materials in concrete, construction and industry. It is made of low carbon steel wire, stainless steel wire after welding and surface treating. Weld […]

Hot Dip Galvanized Steel Field Fence

Product information: Field Fence also called Grassland Fence,Cattle Fence,Kraal Network Fence,Farm Fence is a widely used in America and Europe.Field fence is manufactured in a wid […]

Pvc Coated Wire Mesh

Product information: PVC coated welded mesh Mesh size Wire diameter (in mm) Width&Length In inch In mm Before coating After coating Width:0.5m-2.0m Length:25m,30m […]

Hardware Cloth

Product information: Welded wire mesh is welded form superior low carbon steel wire and then galvanized or pvc coated or stainless steel wire and then welded. It features smooth su […]

Dog Cage

Factory wholesale large metal multi functional dog cage kennel outdoor About the dog cage: * SAFE FOR DOGS – Our welded wire kennel offers safe protection for dogs of all siz […]

Barbed Wire

Product Information: Barbed Wire Material High quality low carbon steel wire, iron wire, etc. Category 1.Hot dipped galvanized 2.Electric galvanized 3.PVC coated Weving and Charact […]

Anti Climb Wall Spikes

Product information: Big Sized Wall Spike Specification Type Big Sized Wall Spike A Big Sized Wall Spike B Model Number Anti-Climb wall Spikes Material HOT DIPPED GALVANIZED STAINL […]

Chain Link Fence

Product information: Specification: Galvanized chain link fence Mesh Wire gauge Width Length 1″ BWG11,12,13,14 0.5-4m 0.5-25m 1-1/2″ BWG8,9,10,11,12,13 0.5-4m 0.5-25m 2 […]

Post time:2023-08-09