Numerous applications have contributed to the popularity of wire mesh, which is manufactured using woven metal wires. This multifunctional material can be utilized for fencing, screening, filtering, and even decoration, and it comes in various materials, sizes, and forms. As a result, wire mesh has profound implications for industrial and commercial settings.

Forging varied metals into strands, a rectangular weaving pattern is used to construct wire mesh. Alloys of stainless steel, bronze, aluminum, brass and copper are utilized in these fibrous expressions of form. Typically galvanized steel predominates the most popular wire mesh variants, yet stainless steel is unobtrusively added to enhance resistance to corrosion degradation.

When strength and lasting durability are required, wire mesh is typically the way to go. This material can be found in fences, screens, sieves, industrial filtrations and separations, cooling systems, as well as decorative art pieces, wall coverings, and even jewelry. No matter the application, wire mesh is sure to do the job.

Varieties of wire mesh come in a wide range of sizes and shapes. The 6, 8, 10, 12, and 16 mesh are among the most frequently encountered. The size number in ‘mesh’ indicates how many strands each inch of it contains – with a greater number translating to a smaller mesh size. To put it simply, if the mesh is marked 6 mesh, then within the span of one inch there will be six strands incorporated into it.

When deciding on the right wire mesh for an application, there are a few factors to weigh in. From the size to the material used and from strength to durability- it’s crucial that every element of the mesh be taken into account. The size of the mesh- bigger will create a mesh with more strength while a smaller size will perform less strong. The material, such as stainless steel, is known to be one of the highest quality and most resilient metal for a durable mesh. All these elements need to be analyzed together when picking out the perfect wire mesh for an application.

When selecting wire mesh for any purpose, its use must be taken into account. If the mesh is to form a fence, its strength and resilience should be ensured to ensure it can withstand any weather conditions. Alternatively, if the mesh is purely for decoration, ease of manipulation and its light weight should be prioritized.

Wire mesh is a tangible solution for a variety of projects, from everyday uses to industrial needs. It has the strength and resilience for multiple purposes and can come in an abundance of sizes, materials, and forms. If the goal is to purchase a reliable and hard-wearing material that can serve a number of objectives, then wire mesh will offer the answers you require.

Wire mesh is a sturdy and functional material that has gained tremendous traction and popularity in a multitude of professions, businesses, and households. In the following passage, we’ll examine six of the most popular styles of wire meshes, as well as what makes them outstanding choices.

One of the more resilient varieties of wire meshes is galvanized steel mesh. As this type is incredibly hard-wearing, it is often employed in industrial set-ups. Additionally, it has been proven to be highly resistant to corrosion; making it the ideal material for protective fencing and barriers often found at security facilities, or for use in agricultural projects such as animal cages and chicken coops.

Stainless steel mesh is a logical choice for applications that prioritize sustainability and longevity, specifically marine and chemical processing. Not only does this type of wire mesh provide superior corrosion resistance, but the sleek and shiny finish also supports must desired aesthetic effects – from decorative fencing to a trusty security barrier.

Arguably the most versatile of all, aluminum mesh is a decidedly practical option. Aside from its lightweight and flexible nature that makes it great for outdoor uses like awnings, fences, and gazebos, it is also commonly employed in industrial settings for effective noise and air filtration systems. All in all, an effective and efficient material suitable for a wide range of purposes and applications.

With its waterproof capabilities and enhancement to extreme temperatures, vinyl-coated mesh is the ideal application for those looking for outdoor solutions. Its durability not only makes it great for fences but also adds beauty to trellises and garden walls – perfect for aesthetic decorative settings.

When it comes to keeping pests away from residential patios and gardens, plastic mesh is a go-to for many. Its use is also great for building window screens and different kinds of outdoor barriers. As the fifth type of wire mesh, this solution can offer homeowners much-needed protection.

For aesthetic and functional purposes, plastic-coated mesh is ideal. This type of wire mesh is designed to be resistant to corrosion, making it a great option for both indoor and outdoor settings. In addition, the plastic coating ensures that it remains easy-to-clean, making it the perfect choice for designing fences or outdoor furniture with style and durability in mind.

Whether you need to secure, filter, enclose, or support something, there is likely a certain type of wire mesh that can get the job done. This exceedingly versatile and long-lasting material is common in various industries as a result of its many benefits. It can help accomplish both large-scale industrial tasks and small-scale residential jobs alike.

Related Product

Chicken Cage

Product information: A type 3 tiers for 96-120 chickens Type A type, 3 tiers A type, 3 tiers A type, 3 tiers A type, 3 tiers Size per unit 1.88m*1.8m*1.6m 2.0m*1.8m*1.62m 2.2m*2.4m […]

Hot Dip Galvanized Steel Field Fence

Product information: Field Fence also called Grassland Fence,Cattle Fence,Kraal Network Fence,Farm Fence is a widely used in America and Europe.Field fence is manufactured in a wid […]

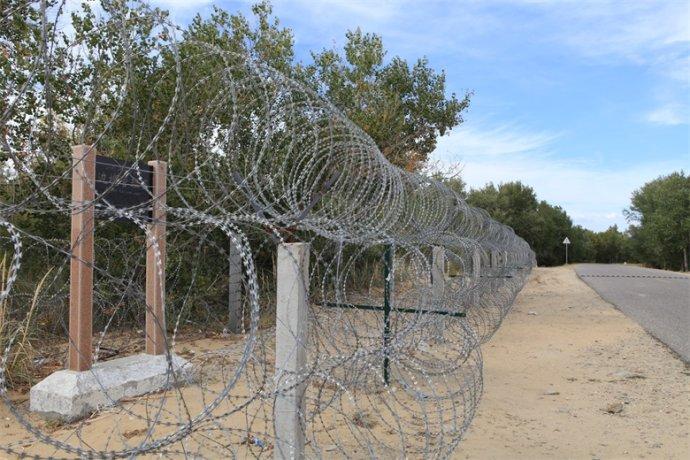

Razor Wire

Product information: Concertina Razor Wire is widely used for construction of high security fencing projects in military and national defence. We export directly and supply Razor W […]

Hardware Cloth

Product information: Welded wire mesh is welded form superior low carbon steel wire and then galvanized or pvc coated or stainless steel wire and then welded. It features smooth su […]

Barbed Wire

Product Information: Barbed Wire Material High quality low carbon steel wire, iron wire, etc. Category 1.Hot dipped galvanized 2.Electric galvanized 3.PVC coated Weving and Charact […]

Chain Link Fence

Product information: Specification: Galvanized chain link fence Mesh Wire gauge Width Length 1″ BWG11,12,13,14 0.5-4m 0.5-25m 1-1/2″ BWG8,9,10,11,12,13 0.5-4m 0.5-25m 2 […]

Welded Wire Mesh Panels

Product information: 1.Materials:Stainless steel wire, Low carbon steel wire, Galvanized wire 2.Style: (1)Electro or Hot dipped galvanized after or before welding; (2)Stainless ste […]

Welded Wire Mesh

Welded wire mesh is one popular materials in concrete, construction and industry. It is made of low carbon steel wire, stainless steel wire after welding and surface treating. Weld […]

Anti Climb Wall Spikes

Product information: Big Sized Wall Spike Specification Type Big Sized Wall Spike A Big Sized Wall Spike B Model Number Anti-Climb wall Spikes Material HOT DIPPED GALVANIZED STAINL […]

Post time:2023-07-18